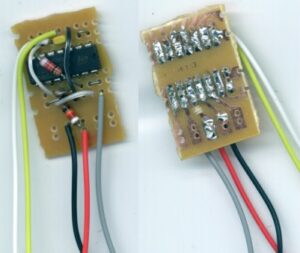

Fuel Cut Defencer PCB Card Cloning has become a topic of growing interest within the automotive tuning and motorsport industries. A Fuel Cut Defencer (FCD) is a specialized electronic circuit board (PCB) designed to modify or extend the factory fuel cut-off settings in a vehicle’s engine control unit (ECU). This allows for higher boost levels in turbocharged engines, enabling enhanced performance without triggering safety restrictions. The unique structure and function of a Fuel Cut Defencer PCB present both exciting possibilities and significant challenges when attempting to clone, replicate, duplicate, reverse engineer, restore, recover, reproduce, modify, or remanufacture these boards.

A clonagem de placas PCB Fuel Cut Defender tornou-se um tópico de crescente interesse nas indústrias de tuning automotivo e automobilismo. Uma Fuel Cut Defender (FCD) é uma placa de circuito eletrônico (PCB) especializada, projetada para modificar ou estender as configurações de corte de combustível de fábrica na unidade de controle do motor (ECU) de um veículo. Isso permite níveis de turbo mais altos em motores turboalimentados, proporcionando melhor desempenho sem acionar restrições de segurança. A estrutura e a função exclusivas de uma PCB Fuel Cut Defender apresentam possibilidades empolgantes e desafios significativos ao tentar clonar, replicar, duplicar, fazer engenharia reversa, restaurar, recuperar, reproduzir, modificar ou remanufaturar essas placas.

Unique Features of Fuel Cut Defencer Circuit Boards

Fuel Cut Defencer PCBs are built with a few critical design elements that differentiate them from standard printed circuit boards:

-

Precision Analog Signal Processing: The board must read and manipulate sensitive signals from sensors like the MAP (Manifold Absolute Pressure) sensor without introducing significant noise or delay.

-

Real-Time Response: FCDs must react within milliseconds to ensure that the modified fuel cut-off point is applied accurately under dynamic driving conditions.

-

High Reliability: The board operates under harsh automotive environments, exposed to vibrations, heat, and electrical noise, requiring robust layout and component selection.

-

Compact Form Factor: Most FCD PCBs are compact to fit within limited engine bay spaces, often using dense layout drawings and multilayer PCB designs.

Because of these specialized requirements, successful Fuel Cut Defencer PCB Card Cloning is far more complex than simply copying a standard PCB design.

Fuel Cut Defender PCB Kartı Kopyalama, otomotiv ayarlama ve motor sporları endüstrilerinde giderek artan bir ilgi konusu haline geldi. Fuel Cut Defender (FCD), bir aracın motor kontrol ünitesindeki (ECU) fabrika yakıt kesme ayarlarını değiştirmek veya genişletmek için tasarlanmış özel bir elektronik devre kartıdır (PCB). Bu, turboşarjlı motorlarda daha yüksek güçlendirme seviyelerine olanak tanır ve güvenlik kısıtlamalarını tetiklemeden gelişmiş performans sağlar. Fuel Cut Defender PCB’nin benzersiz yapısı ve işlevi, bu kartları klonlamaya, çoğaltmaya, kopyalamaya, tersine mühendislik yapmaya, geri yüklemeye, kurtarmaya, yeniden üretmeye, değiştirmeye veya yeniden üretmeye çalışırken hem heyecan verici olasılıklar hem de önemli zorluklar sunar.

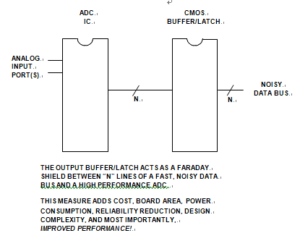

If we have a high resolution data converter (ADC or DAC) connected to a high speed data bus which carries logic noise generated from Fuel Cut Defencer PCB Card Cloning with a 2 V/ns to 5 V/ns edge rate, this noise is easily connected to the converter analog port via stray capacitance across the device. Whenever the data bus is active, intolerable amounts of noise are capacitively coupled into the analog port, thus seriously degrading performance.

A High Speed ADC IC Sitting on a Fast Data Bus Couples Digital Noise into the Analog Port, thus Limiting Performance

This particular effect is illustrated by the diagram of above Figure, where multiple package capacitors couple noisy edge signals from the data bus into the analog input of an ADC.

Present technology offers no cure for this problem even with PCB reverse engineering, within the affected IC device itself. The problem also limits performance possible from other broadband monolithic mixed signal ICs with single chip analog and digital circuits. Fortunately, this coupled noise problem can be simply avoided, by not connecting the data bus directly to the converter.

Challenges in Reverse Engineering and Cloning

Several challenges arise when trying to reverse engineer and clone an FCD PCB:

-

Signal Integrity and Buffer Logic Noise

Automotive environments are rich in electrical noise. Poor PCB layout or inadequate shielding can introduce buffer logic noise, causing erratic operation. Maintaining signal integrity through proper grounding, trace impedance matching, and shielding is crucial during cloning. -

Hidden and Custom Components

Some FCD boards use custom ICs or proprietary discrete logic components not easily identifiable from the physical PCB. Recovering the full BOM list and exact schematic diagram can require specialized techniques such as X-ray imaging or destructive layer-by-layer scanning. -

Precision Layout Complexity

The original layout drawing may have carefully optimized trace lengths and routing paths to preserve signal timing and minimize parasitic capacitance and inductance. Replicating these subtle features requires detailed Gerber file recreation and careful CAD work. -

Environmental Robustness

The cloned board must withstand temperature variations, humidity, and vibration, demanding attention to PCB material selection (such as using high-Tg laminates) and robust solder joint designs.

Instead, use a CMOS latched buffer as a converter-to-bus interface, as shown by below Figure. Now the CMOS buffer IC acts as a Faraday shield, and dramatically reduces noise coupling from the digital bus. This solution costs money, occupies board area, reduces reliability (very slightly), consumes power, and it complicates the design—but it does improve the signal-to-noise ratio of the converter! The designer must decide whether it is worthwhile for individual cases, but in general it is highly recommended.

کلونسازی کارت PCB محافظ سوخت به موضوعی مورد توجه روزافزون در صنایع تیونینگ خودرو و موتوراسپرت تبدیل شده است. محافظ سوخت (FCD) یک برد مدار الکترونیکی (PCB) تخصصی است که برای تغییر یا گسترش تنظیمات قطع سوخت کارخانه در واحد کنترل موتور (ECU) خودرو طراحی شده است. این امر امکان افزایش سطح بوست در موتورهای توربوشارژ را فراهم میکند و عملکرد بهبود یافته را بدون ایجاد محدودیتهای ایمنی امکانپذیر میسازد. ساختار و عملکرد منحصر به فرد PCB محافظ سوخت، امکانات هیجانانگیز و چالشهای قابل توجهی را هنگام تلاش برای شبیهسازی، تکثیر، تکثیر، مهندسی معکوس، بازیابی، بازیابی، تولید مجدد، اصلاح یا بازسازی این بردها ارائه میدهد.

Strategies to Modify and Improve the Design

When cloning or modifying a Fuel Cut Defencer PCB, addressing potential buffer logic noise and improving system stability should be priorities. Here are some strategies:

-

Add Dedicated Ground Planes: Introducing solid, low-impedance ground planes can help isolate sensitive analog and digital sections, reducing noise coupling.

-

Use Proper Decoupling Capacitors: Place low-ESR capacitors close to IC power pins to filter high-frequency noise.

-

Optimize Trace Routing: Avoid long parallel traces between high-speed signals and sensitive analog lines. Route critical paths with controlled impedance.

-

Shield Sensitive Signals: In severe environments, shield critical analog traces with grounded guard traces or employ metal shielding cans.

-

Update Component Choices: Replace outdated op-amps or logic ICs with newer versions featuring lower noise and faster response times for improved performance.

Conclusion

Fuel Cut Defencer PCB Card Cloning is a technically demanding task that requires deep knowledge of PCB design, reverse engineering techniques, and signal integrity management. Understanding the unique features of these critical automotive circuit boards — and the environmental stresses they must endure — is essential to successfully reproduce, modify, and optimize cloned versions. By carefully addressing noise issues, enhancing layout strategies, and ensuring precision reproduction of the original Gerber data, schematic diagrams, and BOM lists, engineers can create reliable and high-performing FCD clones for a new generation of tuned vehicles.