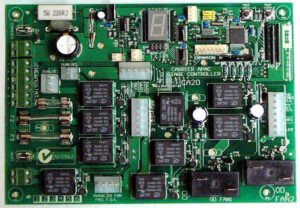

Cooling system HVAC controller PCB board reverse engineering involves several challenges, especially when dealing with older or undocumented units:

Lack of Technical Documentation

Most OEMs do not share the Gerber files, schematic diagrams, BOM lists, or CAD files, which means we must reconstruct them from scratch using precise netlist extraction and visual mapping techniques.

Multilayer & Mixed-Signal Complexity

These boards often have 4–6 layers or more, with signal and power planes carefully routed for EMI performance. Accurate layer-by-layer scanning and reproduction is essential.

A engenharia reversa de placas de circuito impresso controladoras de HVAC para sistemas de refrigeração envolve vários desafios, especialmente ao lidar com unidades mais antigas ou não documentadas: Falta de Documentação Técnica A maioria dos OEMs não compartilha os arquivos Gerber, diagramas esquemáticos, listas de BOM ou arquivos CAD, o que significa que precisamos reconstruí-los do zero usando técnicas precisas de extração de netlist e mapeamento visual. Complexidade Multicamadas e de Sinais Mistos Essas placas geralmente têm de 4 a 6 camadas ou mais, com planos de sinal e potência cuidadosamente roteados para desempenho de EMI. A varredura e a reprodução precisas camada por camada são essenciais.

Component Identification

Many boards use custom or obsolete components, making BOM list reconstruction and sourcing replacements a difficult but crucial step. We use advanced part matching databases and X-ray inspection for hidden ICs.

Firmware Lock or Embedded Logic

Boards with microcontrollers or EEPROMs may contain protected firmware. While we can often reproduce or modify the circuit functions, firmware cloning may require specialized decapsulation or reprogramming.

Manufacturing Considerations

Once reverse-engineered, remanufacturing must replicate the original board’s thermal, electrical, and mechanical characteristics. This includes:

Using high-Tg PCB substrates

Matching solder mask and silkscreen specifications

Ensuring trace width, spacing, and IPC standards compliance

Applying functional testing and in-circuit verification

Why Reverse Engineer HVAC PCBs?

Restore discontinued or unsupported systems

Soğutma sistemi HVAC kontrolör PCB kartının tersine mühendisliği, özellikle eski veya belgelenmemiş ünitelerle uğraşırken çeşitli zorlukları içerir: Teknik Dokümantasyon Eksikliği Çoğu OEM, Gerber dosyalarını, şematik diyagramları, BOM listelerini veya CAD dosyalarını paylaşmaz; bu da bunları hassas netlist çıkarma ve görsel eşleme teknikleri kullanarak sıfırdan yeniden oluşturmamız gerektiği anlamına gelir. Çok Katmanlı ve Karma Sinyal Karmaşıklığı Bu kartlar genellikle 4-6 veya daha fazla katmana sahiptir ve sinyal ve güç düzlemleri EMI performansı için dikkatlice yönlendirilir. Doğru katman katman tarama ve yeniden üretim esastır.

Reduce downtime and dependency on OEMs

Customize board behavior to new environments or controls

Reproduce small batches cost-effectively

Whether you’re facing a failed controller, an obsolete system, or the need to clone, duplicate, or remanufacture a critical board, our engineering team ensures that your cooling system HVAC controller PCB board reverse engineering project delivers precision, performance, and reliability.

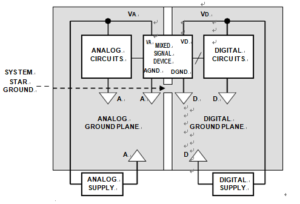

Most ADC, DAC, and other mixed-signal device data sheets discuss grounding relative to Cooling System PCB Board Reverse Engineering, usually the manufacturer’s own evaluation board. This has been a source of confusion when trying to apply these principles to multicard or multi-ADC/DAC systems.

The recommendation is usually to split the PCB ground plane into an analog plane and a digital plane. It is then further recommended that the AGND and DGND pins of a converter be tied together and that the analog ground plane and digital ground planes be connected at that same point as shown in Figure 12.56. This essentially creates the system “star” ground at the mixed-signal device.

Mixed Signal Grounding in Cooling System PCB Board Reverse Engineering

All noisy digital currents flow through the digital power supply to the digital ground plane and back to the digital supply; they are isolated from the sensitive analog portion of the board. The system star ground occurs where the analog and digital ground planes are joined together at the mixed signal device.

While this approach will generally work in a simple system with a single PCB and single ADC/DAC, it is not optimum for multicard mixed-signal systems. In systems having several ADCs or DACs on different PCBs (or on the same PCB, for that matter), the analog and digital ground planes become connected at several points, creating the possibility of ground loops and making a single- point “star” ground system impossible.

For these reasons, this grounding approach is not recommended for multicard systems, and the approach previously discussed should be used for mixed-signal ICs with low digital currents.

In the HVAC industry, controller boards play a critical role in managing temperature, airflow, diagnostics, and energy efficiency. These cooling system HVAC controller PCB boards often include intelligent control logic, real-time communication protocols, and fault-detection systems that ensure long-term performance and safety. When these boards fail, are discontinued, or require customization, the need for cooling system HVAC controller PCB board reverse engineering becomes urgent and essential.

We specialize in cloning, replicating, modifying, and remanufacturing HVAC controller circuit boards with a focus on reliability and functional integrity. Our reverse engineering service supports a full spectrum of legacy and proprietary HVAC PCBs, especially those that feature onboard diagnostic capabilities.

Зачем проводить реверс-инжиниринг печатных плат HVAC? Восстановление снятых с производства или неподдерживаемых систем Сокращение простоев и зависимости от OEM-производителей Настройка поведения платы в соответствии с новыми средами или элементами управления Воспроизведение небольших партий с минимальными затратами Независимо от того, сталкиваетесь ли вы с неисправным контроллером, устаревшей системой или необходимостью клонирования, копирования или восстановления важной платы, наша инженерная команда гарантирует, что ваш проект по обратному проектированию печатной платы контроллера системы охлаждения HVAC обеспечит точность, производительность и надежность.

Unique Features of HVAC Diagnostic Controller PCBs

HVAC controller PCBs are not simply switchboards; they act as intelligent hubs that monitor and control the entire system. Many modern units include:

-

Sensor input handling for temperature, humidity, pressure, and refrigerant levels

-

Onboard diagnostics for real-time fault codes and error logging

-

Communication interfaces such as RS-485, Modbus, or CAN for integration into BMS (Building Management Systems)

-

Microcontroller or embedded processor units for programmed control logic

-

Power regulation modules for fan motors, compressors, and actuator control

-

Fail-safe protection mechanisms for overcurrent, overvoltage, or short-circuit conditions

These features are often tightly integrated into a multilayer PCB layout, involving a combination of analog and digital signals, isolated power zones, and noise-sensitive traces.